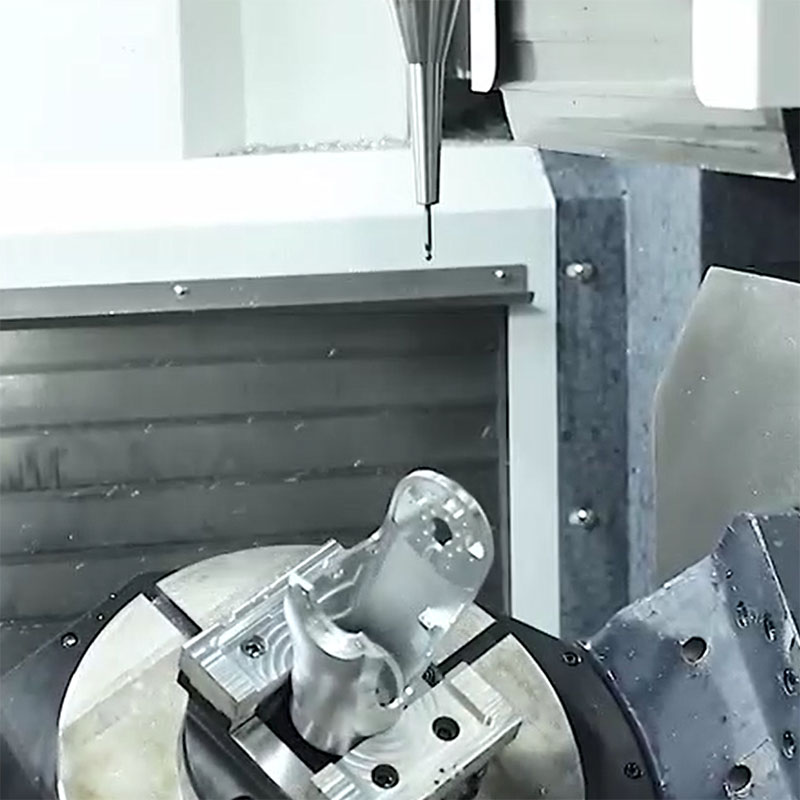

| Product Name | High-Accuracy CNC 5 axis AI Robot parts Machining OEM/ODM |

| Business Type | Factory & Manufacturer |

| Certificate | ISO 9001:2015 |

| Service | CNC machining ,milling & turning , sheet metal fabrication, grinding, deburring, tapping, drilling, cutting, knurling, laser marking, wire EDM, CAM programming and outsource service |

| Material | Stainless Steel: 303, 304, 304L, 316, 316L, etc… Carbon Steel: 1018, 1045, 1144, 12L14, 1215… Aluminum: 5052, 6061-T6, 6061-T4, 6082-T6, 6063-T6… Brass and Copper: C3602, C3604, H62, C34000 Plastic: POM, PEEK, ABS, PA66, PP, PMMA etc… Titanium and more… |

| Finish | sandblasting, anodizing, blackening, plating, polishing, coating, knurling and more |

| Equipment | CNC milling machine, CNC turning machine, auto lathe, grinding machine, tapping machine, drilling machine, laser marking machine, WEDM machine, CMM machine and more. |

| Drawing Format | STEP, STP, GIS, CAD, PDF ,DWG ,DXF etc or samples. |

| Inspect Tool | CMM,Projector, micrometer, thread gauges, calipers, pin gauge, altimeter and more. |

| Quality Control | Quality Control |

| Tolerance | +/-0.01mm ~ +/-0.001mm or as per client’s needs |

| Surface Roughness | Ra 0.1~3.2 or as per client’s needs |

| Additional Service | assembly, logo engraving, surface finish, special package etc. |

Write your message here and send it to us