Products

-

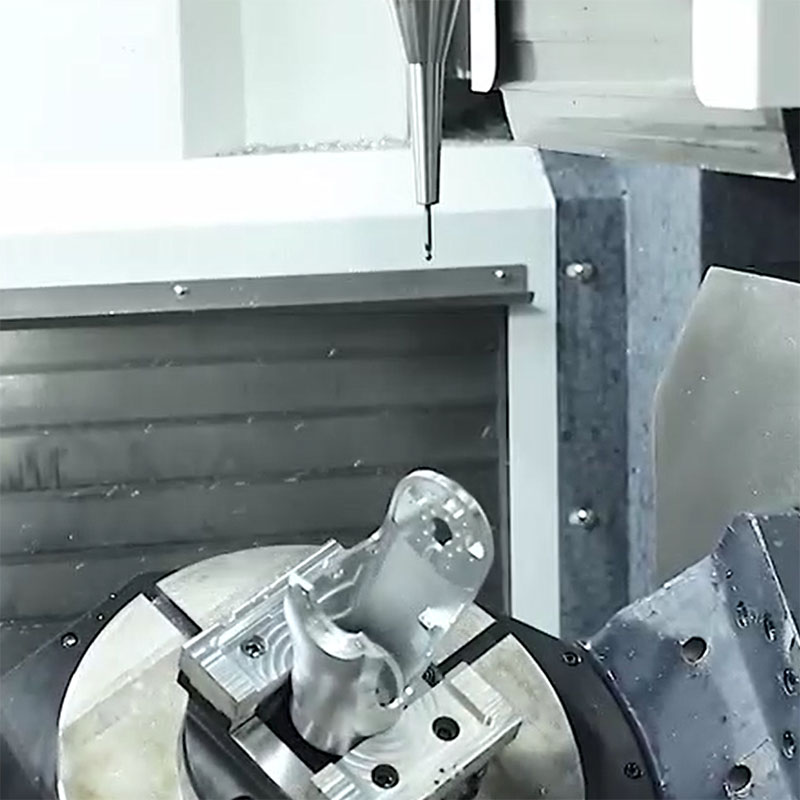

CNC 5 axis machining spindle rear left and right OEM gold anodized CNC car parts

5-axis machining for racing parts offers micron-level precision on complex designs like CNC spindle rear components, ensuring aerodynamic surfaces and minimal post-processing. It reduces setup errors, supports high-strength materials (titanium/carbon fiber), and enables rapid prototyping. With AI-optimized toolpaths, it meets racing’s need for lightweight, durable parts. Its small-batch customization and additive manufacturing integration drive future motorsport innovation.

-

Customizable 5 Axis Robot Arm Parts Artificial Intelligence Robot Shell Robot Parts One-Stop Processing CNC Machining Service

Advanced Manufacturing Capabilities: Pioneering AI Robot Component Production with State-of-the-Art Five-Axis Equipment

Shenzhen Jing Si Dun Mechanical Equipment Co., Ltd. stands at the forefront of precision manufacturing, distinguished by a massive fleet of state-of-the-art five-axis machining centers that form the backbone of our production excellence. These cutting-edge systems, renowned for their unparalleled accuracy and versatility, enable us to tackle the most complex geometries and tight-tolerance requirements demanded by AI intelligent robot components. Unlike traditional machining setups, our five-axis equipment allows simultaneous movement along five axes, ensuring seamless production of intricate parts—from robotic arm joints and sensor housings to precision gears—with minimal setup times and maximum efficiency. This technological edge positions us as a leader in an industry where component precision directly impacts robotic functionality, durability, and performance.With years of specialized experience in crafting components for AI-driven robotics, our factory has honed a unique expertise that merges technical innovation with practical manufacturing know-how. We understand that AI robots require components that balance lightweight design with structural integrity, often integrating electronics and mechanics in seamless harmony. Our team of engineers and technicians, backed by decades of combined industry experience, has successfully delivered the most challenging projects for global robotics innovators. From prototyping to mass production, we leverage our five-axis capabilities to streamline workflows—reducing errors, enhancing repeatability, and ensuring every part meets the rigorous standards of AI robotics, where reliability is non-negotiable.What truly sets us apart is the synergy between our advanced equipment and deep industry insight. Our large-scale deployment of five-axis machines not only enables high-volume production but also offers unmatched flexibility for custom solutions. Whether clients need micro-precision parts for delicate robotic sensors or heavy-duty components for industrial robots, our setup allows rapid retooling and adaptive manufacturing. Moreover, our rigorous quality control processes—integrated at every stage from design to delivery—ensure that each component undergoes meticulous testing, guaranteeing compatibility with AI systems and compliance with international standards.In an era where AI robotics is reshaping industries, our factory’s commitment to investing in top-tier five-axis technology and nurturing manufacturing expertise places us at the core of innovation. We don’t just produce parts; we craft the building blocks of next-generation AI robots, driving progress through precision, reliability, and a proven track record of excellence.

-

Pom Bicycle Lock For CNC Custom

A POM transmission lock refers to a transmission lock manufactured using polymer (POM, also known as polyoxymethylene) material. POM is a high-quality engineering plastic with high wear resistance, low coefficient of friction and excellent mechanical properties.

The transmission lock made of POM material is durable, lightweight and corrosion-resistant. It can better withstand the pressure and friction of the transmission, which provides longer service life and more reliable shifting function.

In addition, the POM material also has high heat resistance and chemical corrosion resistance, so that the POM transmission lock can maintain good performance in various working environments.

-

Precision custom CNC Machining parts CNC turning anodized aluminum parts CNC lathe turning parts for trekking poles

Optional materials: Aluminum; Stainless steel; Plastic; Titanium

Surface Treatment: Anodized; Plating; Powder coating; Sandblasting; Polishing

The application: Multifunctional trekking pole

-

OEM CNC machining parts stainless steel lathe parts with electrolytic polishing cnc turning service for Underwater camera

Optional materials:Stainless steel; Aluminum; Titanium

Surface Treatment: Electrolytic polishing; Plating; Hard anodized

The application: Underwater camera/imaging equipment

CNC turning service is a type of CNC machining process where a cylindrical workpiece is rotated while a cutting tool removes material to create the desired shape. This is done using a CNC lathe machine, which is computer-controlled to precisely move the cutting tool and create highly accurate and consistent parts.

-

CNC turning machining knurling high-end aluminum flashlight case

Process: CNC Machining Centers & CNC lathe

Material: Micarta

Optional materials: Micarta, Aluminum, Steel, Brass, Staniless steel, Plastic, Titanium etc

Surface Treatment:Anodized, Spray powder, Nickel plating, Zinc plating, Chrome plating, Gold plating, Black oxidation, Polishing

The application: flashlight housing

-

Anodized Turning Lathe Components CNC Spare Parts Custom Cnc Machining Part For Guitar Parts

Material: SS 304

Optional materials: Aluminum/stainless steel/brass etc.

Surface Treatment: Sandblasting/anodizing/Brushed /electroplating, etc.

The application: guitar parts

-

High precision CNC milling parts anodized aluminium 7075 t6 CNC machining parts Custom scooter part

Material: Al-6061-T6

Optional materials:Aluminum; Stainless steel; Plastic; Brass; Titanium

Surface Treatment: Anodized; Plating; Powder coating; Sandblasting

The application: Snow Scooter/Scooter

-

Precision 3d printing service plastic 3d printing rapid prototype model design 3D printing parts

Optional materials: ABS; PLA; PC NYLON

Application:artware

Custom 3D printing parts refer to the process of creating unique and personalized objects using a 3D printer. This technology allows you to produce objects with complex shapes and customized features based on your specific requirements or design specifications.

-

High quality CNC milling micarta parts for screw machine

Material: Micarta

Optional materials: Aluminum, Steel, Brass, Staniless steel, Plastic, Titanium etc

Processing Methods: CNC milling machining

Surface Treatment: Anodized, Spray powder, Nickel plating, Zinc plating, Chrome plating, Gold plating, Black oxidation, Polishing

The application: Screw machine

-

Custom aluminum CNC Machining Part CNC Milling Aluminum Anodizing Fabrication Parts For Racing Motorcycle Parts

Material: Al 7075

Optional materials: Aluminum; Stainless steel; Titanium

Surface Treatment: Anodized; Plating; Powder coating; Polishing; Sandblasting; Nitriding

The application: racing motorcycle

CNC machining parts for motorcycles have various applications and advantages. CNC (Computer Numerical Control) machining is a precise manufacturing method that brings numerous benefits to the motorcycle industry.

-

Custom CNC Machining Part Aluminum Sheet Metal Precision Turning Parts For DIY Making

Material: Al 6061

Optional materials: Stainless steel; Steel; aluminum; Brass etc.,

Application: Radiator accessories

Customized sheet metal parts play a crucial role in the functioning and performance of radiators. These parts are specifically designed and manufactured to fit the unique specifications and requirements of each radiator system. From fins to covers, brackets, and baffles, customized sheet metal parts offer numerous benefits in terms of efficiency, durability, and aesthetics.